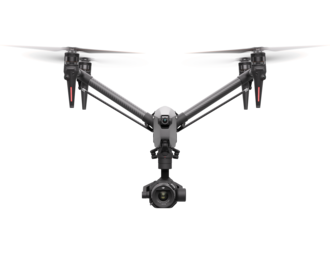

The Future of Mining is Here: Automating Workflows with the DJI Dock

In mining, data is everything. But capturing that data from vast, remote, and often hazardous sites is a constant challenge. Traditional methods are slow, tie up skilled personnel, and create significant safety risks.

That's why dock-based automation is redefining how mining teams capture, process, and act on-site data. With solutions like the DJI Dock and FlightHub 2, operations can schedule and launch missions remotely, automatically sync imagery on landing, and trigger automated processing.

This isn't just a concept; it's a proven path from pilot-dependent flights to a BVLOS-ready programme. We're exploring the key findings from a new white paper, "Implementing an Automated Mining Workflow using DJI Dock", which details how this technology is creating safer, more efficient, and more decisive operations.

From Hours to Minutes: The Case for Automation

Switching from manual drone flights to an automated dock solution delivers a powerful and immediate return on investment. The white paper highlights a massive uplift in productivity.

• Drastic Cycle-Time Reduction: In controlled deployments, sites saw post-blast survey cycles drop from 1.2 hours to just 0.5 hours (including capture and processing). This is achieved through rapid remote launches, automatic media uploads, and integrated photogrammetry.

• Massive Scalability: A single DJI Dock can support up to 50 flight hours per month (about 150-200 individual flights). These flights can be managed with "one-to-many" oversight from a single Remote Operating Centre (ROC), freeing your most skilled people from repetitive tasks.

• Enhanced On-Site Safety: The primary benefit is removing personnel from hazardous environments. The dock workflow allows pilots to operate from a safe, remote location, drastically reducing on-site exposure in active pits.

• Standardised Data, Faster Decisions: Automation eliminates human variability. It standardises data quality and timing across all shifts and locations, breaking down information silos and empowering teams with near real-time insights for faster, better decision-making.

A Proven Workflow for Every Mining Task

The white paper details how this automated approach is already being applied to the most critical mining tasks. Case studies from industry giants like Rio Tinto and Norton Gold Fields demonstrate proven ROI across the board.

The guide provides a blueprint for:

• Automated Surveying: Daily volumetric measurements, stockpile calculations, and conformance checks.

• Post-Blast Analysis: Rapidly map muckpiles to optimise grade control and recovery.

• Asset & Pipeline Inspections: Schedule regular, repeatable thermal and visual inspections of conveyors, plants, pipelines, and other critical infrastructure.

• Compliance & Reporting: Automate environmental monitoring, berm height checks, and land disturbance mapping.

• Emergency Response: Launch a drone in minutes to provide real-time aerial awareness to incident command without putting a response team at risk.

The "How": Implementing Automation with Ferntech

As the white paper explains, implementing a "drone-in-a-box" system is a complex undertaking. It requires a deep understanding of regulatory compliance, including Beyond Visual Line of Sight (BVLOS) approvals, SORA risk assessments, and Remote Operating Centre (ROC) certification.

This is where you need a technology partner, not just a hardware supplier. Ferntech is New Zealand's premier drone company, and we have built a complete, end-to-end programme to get you operational faster and more reliably than anyone else.

1. A Proven Pathway to BVLOS Approval Ferntech is at the forefront of autonomous drone operations in New Zealand. We run our own Remote Operations Centre (ROC) from our Auckland headquarters and have successfully achieved Civil Aviation Authority (CAA) approval for autonomous BVLOS operations. We have executed hundreds of autonomous flights for major New Zealand infrastructure clients, giving us unparalleled real-world experience.

2. Managed Services: Get Airborne in Months, Not Years For clients who want to bypass the significant regulatory hurdles, we offer a fully managed flight service through our sister company, Beyond UAV. This service allows you to leverage our existing Part 102 certification and operational expertise. Instead of waiting 8-12+ months for your own regulatory approvals, our team can get your site-specific approvals (SORA) sorted in a fraction of the time, getting your programme airborne and delivering data faster.

3. Turnkey, Rapid Deployment We have designed a self-contained, skid-based system for rapid deployment. This robust, relocatable unit includes the DJI Dock, redundant communications (like dual Starlink), and all required airspace monitoring hardware (ADSB/VHF). It's a true "plug-and-play" solution ideal for remote sites with minimal infrastructure.

4. End-to-End Certified Support As New Zealand's only DJI Gold Partner and only DJI-certified commercial repair centre, we provide a level of support no one else can match. Our service includes:

• Initial Consultation and feasibility assessments, including site-specific viewshed analysis.

• Full Hardware Integration and on-site setup.

• Certified Operator Training (101/102) for your team.

• Ongoing Maintenance and local, warranty-backed servicing.

Take the Next Step

The DJI Dock system offers a revolutionary leap in mining productivity, safety, and data quality.

To dive into the full details, download the complete white paper from our technology partner, DJI:

If you are ready to explore how this technology can be integrated into your New Zealand operation, contact the expert team at Ferntech below.